Trailers, indispensable in numerous industries and daily applications, come in various types to cater to specific needs. Each type of trailer is unique in terms of size, weight, and use, reflecting the diverse requirements of different sectors. This comprehensive guide provides a detailed look into different types of trailers, highlighting the features, uses, and key brands of each class.

The type of trailer you need differs depending on whether you need to secure cargo and transport goods securely, transport lawn mowers, or desire an easy loading landscape trailer or one with easy lube hubs.

Trailers have a wide array of industrial applications. They serve construction sites, movie production sets, local supply transport, portable dressing rooms, and more. Their capacity to haul heavy machinery, supplies, and other materials makes them an indispensable part of many industries.

Trailers are also used in lots of personal projects and adventures. They are handy in moving to a new home, going on camping trips, or serving as a base for DIY projects like food trucks or tiny houses.

How Many Types of Trailers Are There?

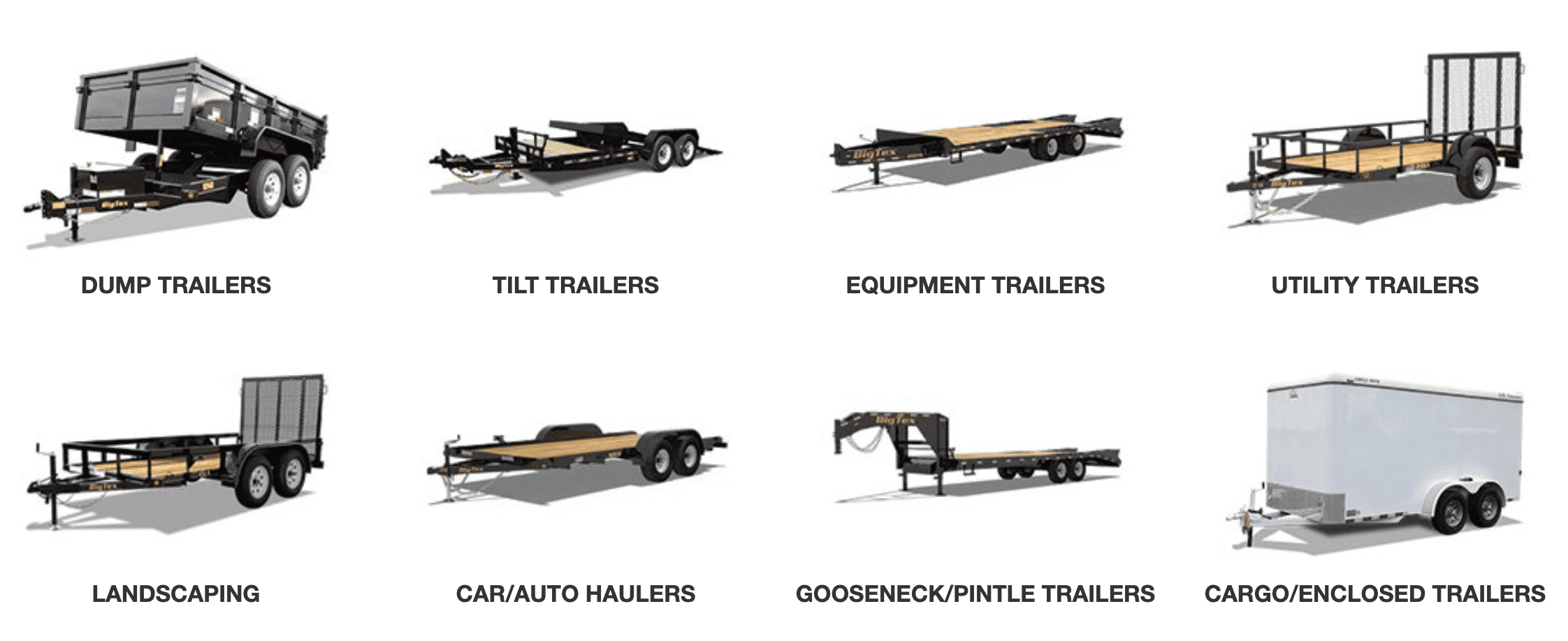

There are primarily 8 types of trailers. Trailer types are as multifaceted as the functions they serve. From carrying construction materials and equipment to serving as a mobile storage unit, trailers are designed to fulfill a plethora of requirements.

Well-established trailer manufacturers such as Workhorse Trailers and Featherlite Trailers offer a wide variety of options, ensuring that there’s a perfect fit for everyone’s needs. When selecting your trailer, it’s helpful to search phrases such as ‘utility trailers for sale near me’, ‘heartland utility trailer reviews’, or ‘dump trailers for sale near me’, which can lead you to numerous options.

An In-Depth Look at Different Trailer Types

There are many different types of trailers. There are dump, tilt, equipment, landscaping, car hauler, gooseneck, and cargo (also called enclosed) trailers. And every kind of trailer can be used differently.

Dump Trailers

Dump trailers are one of the toughest trailers out there. They are typically constructed with a heavier-duty frame than most cargo trailers. This is necessary to support loads of dirt, gravel, and other aggregate or debris these types of trailers usually haul.

Dump trailers are designed to handle heavy loads, so their bolt patterns often align with those found on medium to heavy-duty trailers. The exact bolt pattern can vary based on the size of the trailer, the intended load capacity, and the manufacturer’s design choices.

Typically, for dump trailers, you might encounter the following bolt patterns:

- 6×5.5 (6×139.7mm): Common for some medium-duty trailers.

- 8×6.5 (8×165.1mm): Found on many heavy-duty trailers, and is also a common bolt pattern for 3/4-ton and 1-ton trucks.

- 8x170mm: This is specific to some models of Ford heavy-duty trucks but can also be found on certain trailer models.

- 8x200mm: Found on some of the newer Ford F-450 and F-550 trucks and might be seen on trailers designed to be compatible with these vehicles.

Some of the best dump trailers might include a roll-down tarp for covering a load and preventing it from blowing out of the trailer. They may also include a toolbox, a heavier-duty jack stand, and a spare tire mount.

There are also different brands of trailers. For help choosing your trailer company, a few to look at include Kaufman, Big Tex, PJ, MaxxD, and Diamond C.

Tilt Trailers

Tilt trailers are built with a tilting bed mechanism. This can be found on car haulers, equipment trailers, and dump trailers.

Tilt trailers come in various sizes and capacities, from smaller single-axle trailers to larger, heavy-duty dual or triple axle trailers. The bolt pattern for a tilt trailer will largely depend on its design, weight capacity, and intended use.

Here are some typical bolt patterns that you might find on tilt trailers:

- 5×4.5 (5×114.3mm): This is common for smaller, single-axle trailers often used for hauling lighter items like ATVs, small equipment, or garden tractors.

- 5×5 (5x127mm) or 5×5.5 (5×139.7mm): These patterns are found on medium-duty trailers, suitable for a wider range of tasks and slightly heavier loads.

- 6×5.5 (6×139.7mm): Found on larger, medium-duty trailers. This bolt pattern is also common on many light trucks.

- 8×6.5 (8×165.1mm): A common bolt pattern for heavy-duty tilt trailers designed to haul larger equipment, vehicles, or other heavy loads. This pattern is also typical of 3/4-ton and 1-ton trucks.

The best tilt trailers make it easier to load and unload certain cargo or equipment. With a ramp that tilts to meet the ground, vehicles can be driven onto these types of trailers, and heavy cargo can be rolled or carried on more easily.

Equipment Trailers

An equipment trailer is any trailer capable of transporting equipment. They are similar to a standard utility trailer. However, most equipment trailers have beefed-up frames and other components to accommodate heavier loads.

These trailers typically come in two types – flatbed and deckover. The differences between a flatbed and deckover trailer mostly come down to the width and height of the deck or bed of the trailer.

Equipment trailers are designed to haul heavy machinery and equipment, often used in construction, agriculture, or other industries. Given their purpose, these trailers tend to be robust and have bolt patterns associated with heavy-duty applications. However, the exact bolt pattern will vary based on the trailer’s size, load capacity, and the manufacturer’s design.

Here are some typical bolt patterns you might encounter on equipment trailers:

- 6×5.5 (6×139.7mm): This is more common for medium-duty trailers, suitable for carrying smaller equipment like garden tractors, ATVs, or UTVs.

- 8×6.5 (8×165.1mm): A prevalent bolt pattern for heavy-duty equipment trailers. This pattern is designed to accommodate the weight of larger machines like excavators, skid-steers, or tractors. It’s also a common bolt pattern on 3/4-ton and 1-ton trucks.

- 8x170mm: Specific to some models of Ford heavy-duty trucks, but you might also encounter this bolt pattern on trailers designed to be compatible with these vehicles.

- 8x200mm: Less common but can be found on some trailers, especially those intended to pair with newer Ford F-450 and F-550 trucks.

Equipment trailers can be used by heavy equipment operators to haul heavy equipment. These types of trailers are typically used to haul small tractors, various equipment, and even automobiles. They are equipped with heavy-duty tie-downs, hardwood plank floors, and winches.

Utility Trailers

The best utility trailer is a simpler design than cargo trailers. They are one of the most common types of trailers and are typically constructed on the same heavy-duty steel tube frame.

Utility trailers also have various drop leaf spring axle configurations – such as tandem axle utility trailers – for carrying loads of different weights.

Utility trailers are versatile and come in a range of sizes and capacities, from small single-axle trailers used for lawn equipment to larger dual-axle trailers for more substantial loads. The bolt pattern of a utility trailer will depend on its size, design, and intended load capacity.

Here are some typical bolt patterns you might encounter on utility trailers:

- 4×4 (4×101.6mm): Common for very small, lightweight utility trailers, often used for hauling items like lawn mowers or personal goods.

- 5×4.5 (5×114.3mm): This is prevalent for smaller to medium-sized single-axle utility trailers. It’s a standard pattern also found on many passenger vehicles.

- 5×5 (5x127mm) or 5×5.5 (5×139.7mm): You might find these on medium-duty trailers, suitable for a broader range of tasks.

- 6×5.5 (6×139.7mm): This pattern can be found on larger utility trailers, especially those with a dual-axle setup designed for carrying heavier loads.

However, because they are not enclosed, these types of trailers are not lined with plywood. They also do not have an aluminum skin for protection or overhead lights or vents.

Some do offer a ramp or gate on the back for loading and containing cargo. Most also have a low steel tube frame wall around the perimeter of the trailer.

These trailers also come with all required lighting for road operation. They also come with a jack stand and foot as well as safety chains for towing.

Landscaping Trailers

Landscaping trailers are typically constructed on the same heavy-duty steel tube frame as other types of utility trailers but are usually built for more heavy-duty payloads such as small lawn tractors and other equipment.

Landscaping trailers may have various mounts for equipment like weedeaters and edgers. They may also come in a dual-axle configuration and have various drop leaf spring axle beam configurations for carrying loads of different weights.

Landscape trailers, typically used for transporting landscaping equipment like mowers, tools, mulch, and plants, come in a variety of sizes, from smaller single-axle trailers to larger tandem-axle setups. The bolt pattern on a landscape trailer will depend on its size, load capacity, and the manufacturer’s design.

Here are some common bolt patterns that you might encounter on landscape trailers:

- 4×4 (4×101.6mm): Often found on very small, lightweight landscape trailers. These are suitable for carrying lighter equipment or small loads.

- 5×4.5 (5×114.3mm): Common for small to medium-sized single-axle landscape trailers. This is a standard pattern seen on many passenger vehicles as well.

- 5×5 (5x127mm) or 5×5.5 (5×139.7mm): These might be used for medium-duty landscape trailers, capable of hauling a mix of equipment like mowers, tools, and some material loads.

- 6×5.5 (6×139.7mm): More typical for larger landscape trailers, particularly those with a dual-axle setup. These trailers are designed to carry heavier equipment and more substantial loads.

The best landscaping trailer offers a ramp or gate on the back for loading and containing landscaping equipment or debris. This also makes them great snowmobile trailers. Most also have a low steel tube frame wall around the perimeter of the trailer.

Like some other types of trailers, landscaping trailers also come with all the required lighting for road operation. They also come with a jack stand and foot as well as safety chains for towing.

Car Hauler Trailers

Car hauler trailers are similar to equipment trailers. Some have tilt beds, some have front shields to protect the automobiles they are hauling, and so on.

Car hauler trailers, designed for transporting vehicles, typically have robust construction due to the weight and value of their cargo. The bolt pattern on a car hauler will largely depend on its size, design, and load capacity. However, given that they’re meant to carry vehicles, many car haulers lean toward heavier-duty bolt patterns.

Here are some typical bolt patterns you might encounter on car hauler trailers:

- 5×4.5 (5×114.3mm): Found on smaller, single-axle car haulers or those designed for lighter vehicles, such as compact cars, ATVs, or motorcycles.

- 5×5 (5x127mm) or 5×5.5 (5×139.7mm): Common on medium-duty car haulers, especially those used for average-sized cars or small trucks.

- 6×5.5 (6×139.7mm): This bolt pattern is more common for larger, dual-axle car haulers meant for heavier vehicles or multiple smaller vehicles.

- 8×6.5 (8×165.1mm): For heavy-duty car haulers or those designed for carrying multiple vehicles, this bolt pattern is prevalent. It offers a robust setup suitable for the significant weight these trailers might bear.

The best car hauler trailer also typically has convenient hooks and other features for securing a load specifically for cars and trucks. These trailers are also typically used for tiny home trailers.

Tiny Home Trailers

Tiny homes are often built on flatbed trailers, specifically designed to carry the weight and dimensions of a small residential structure. The tiny house trailer is the foundation of the tiny home and is essential to its mobility.

Here are some tiny house basics of trailers used for tiny homes:

- Size: The length of the trailer typically ranges from 12 to 28 feet (or even longer, depending on the design). The width is often 8.5 feet, which is the maximum width for road-legal towing in most areas without a special permit.

- Weight Capacity: The trailer must be able to support the weight of the tiny home, which usually ranges from 10,000 to 20,000 pounds or more. This depends on the materials used in the construction of the tiny home.

- Type: A flatbed or car hauler trailer is commonly used, with the bed situated between the wheels, which helps to lower the overall height of the structure and makes it easier to build a tiny home on it. Some also prefer a gooseneck trailer, which attaches to the bed of a pickup truck, offering increased stability.

- Axles: Depending on the size and weight of the tiny house, dual or triple axles might be used to evenly distribute the weight.

- Dual Axle (Tandem Axle) Trailers:

- Common axle ratings for tandem axle tiny home trailers range from 3,500 lbs to 7,000 lbs per axle. This means the total weight capacity for the trailer would be between 7,000 lbs (two 3,500 lb axles) to 14,000 lbs (two 7,000 lb axles).

- Triple Axle Trailers:

- For triple axle trailers, the individual axle rating is often the same as dual axle trailers, i.e., between 3,500 lbs to 7,000 lbs per axle. Thus, the total weight capacity for the trailer would range from 10,500 lbs (three 3,500 lb axles) to 21,000 lbs (three 7,000 lb axles).

- Dual Axle (Tandem Axle) Trailers:

- Customizations: Many tiny home builders opt for custom-made trailers, designed specifically for their unique house plans. Features like specific anchor points, a lower deck, or extended frames can be requested to fit the particular design of the tiny home.

- Brakes: Adequate braking systems are essential for safety. Electric brakes are commonly found on tiny house trailers, sometimes supplemented with a brake controller in the towing vehicle.

- Road Compliance: The trailer must comply with local road regulations, including width, length, and weight restrictions. This may influence the design and require specific inspections or certifications.

- Materials and Build Quality: It’s vital to choose a trailer made of quality materials and designed with proper weight distribution and structural integrity in mind.

Before searching for used trailers for sale by owner, it’s always wise to consult with a trailer manufacturer or a specialist in tiny home construction to ensure that the steel car trailer is suited to the specific needs and regulations of the intended tiny home. Check out Appalachian Trailers or Circle B Trailer Sales for more options.

Gooseneck Trailers

Goosenecks are used for hauling serious payloads. When the weight of the load exceeds what is allowed to tow from the bumper, a gooseneck trailer is the next step up.

The best gooseneck trailer is built even heavier than equipment trailers. These types of trailers often have a payload capacity of over 12,000 pounds and are capable of hauling heavy equipment long distances.

Gooseneck trailers, including those designed for hauling cars, are characterized by their unique hitch design, which attaches to the bed of a pickup truck rather than its bumper. These trailers are built for heavier-duty hauling tasks due to the weight distribution advantages and increased stability offered by the gooseneck design.

Gooseneck trailers are commonly used for heavy-duty hauling tasks due to their increased stability and weight distribution advantages provided by the gooseneck hitch, which connects to the bed of a pickup truck. The bolt pattern on a gooseneck trailer will largely depend on its size, design, and intended load capacity. However, given their design for heavier hauling, they often feature robust bolt patterns suitable for substantial weight.

Here are some typical bolt patterns you might encounter on gooseneck trailers:

- 6×5.5 (6×139.7mm): While this is more common for medium-duty trailers, you might find some gooseneck trailers, especially those designed for lighter tasks or smaller loads, with this bolt pattern.

- 8×6.5 (8×165.1mm): This is a prevalent bolt pattern for many heavy-duty gooseneck trailers. It’s suitable for the demands of hauling heavy equipment, livestock, multiple vehicles, and other substantial loads. This bolt pattern is also common on 3/4-ton and 1-ton trucks.

- 8x170mm: Specific to some heavy-duty Ford truck models. Some gooseneck trailers might use this bolt pattern to align with these vehicles.

- 8x200mm: This is less common but can be found on trailers designed to be used with some of the larger Ford trucks, like the F-450 and F-550.

Cargo Trailers

Cargo trailers are also called enclosed trailers and are one of the most popular types of trailers to rent in a rent to own trailer program. These types of trailers are typically constructed on a steel tube frame sitting on one or more drop leaf spring axles. The walls are also usually made from steel tubing for the frame.

Cargo trailers are versatile and are used to transport a wide range of goods, from personal belongings to commercial equipment. Depending on the size and capacity of the cargo trailer, there are different bolt patterns that might be employed. Here are some typical bolt patterns you might encounter on cargo trailers:

- 4×4 (4×101.6mm): Common for very small, lightweight cargo trailers. These trailers are typically used for light duties, such as transporting personal items or small equipment.

- 5×4.5 (5×114.3mm): A prevalent bolt pattern for small to medium-sized single-axle cargo trailers. This pattern is also standard on many passenger cars.

- 5×5 (5x127mm) or 5×5.5 (5×139.7mm): These might be seen on medium-duty cargo trailers that carry a more substantial load, including some dual-axle models.

- 6×5.5 (6×139.7mm): This is more typical for larger cargo trailers, especially those with a dual-axle setup, which are designed for heavier loads.

- 8×6.5 (8×165.1mm): While less common for typical cargo trailers, this bolt pattern can be found on some heavy-duty variants meant for significant weight.

The interior of types of trailers is covered by plywood. Some trailers include interior lighting and most enclosed trailers come with locks and a roof vent. It’s also important to consider essential cargo trailer accessories to go with your enclosed trailer.

The exterior is typically sheathed in aluminum. Most will have a heavy-duty ramp door for loading and unloading and have all required safety lighting for use on public roads and highways.

They will also have a jack with a standing foot for holding the tongue of the trailer level when not connected to a towing vehicle. Cargo trailers will have safety chains for use while being towed that help prevent the trailer from disconnecting completely from the towing vehicle in the event of a hitch or coupler failure.

Maintenance and Care

Maintaining your trailer is essential to ensure its longevity and reliability. Regular inspection of tire pressure, lighting systems, suspension components, and brakes can prevent potential problems down the road. Regular cleaning is also necessary to prevent rust and corrosion, especially in salt-prone winter conditions.

Safety Measures and Regulations

Adhering to safety measures and regulations is a crucial part of trailer ownership. Regular checks of the hitch connection, tire conditions, and brake systems can prevent accidents. Additionally, understanding and complying with state-specific regulations regarding lighting, brakes, and maximum permissible weight is essential.

Buying Tips

When purchasing a trailer, considering its intended use is paramount. This will determine the type and size of the trailer needed. Budget, quality, brand reputation, and new vs. used are other crucial factors to consider.

Learn more about How to Find the Perfect Trailers to Haul ATV or SxS UTVs.

New trailers often come with warranties but at a higher price point, whereas used trailers can be cost-effective but may require repairs. You can find a great selection of used trailers on Trailer Trader, especially if you are looking for a replacement dump trailer and have already shopped multiple trailer dealers.

There are lots of individuals selling trailers on Trailer Trader, everything from Top Hap Trailers and Karavan Trailers to a Diamond C Trailer. You can also find trailer dealers focused on trailer sales and trailer repair, some of which offer the best customer service.

You can also learn more about rent to own trailer programs, types of trailers available for rent to own, advantages of No Credit Check Financing., and how to get started at rent to own trailers.

Summary

As this guide illustrates, the world of trailers is broad and varied, with a solution for every need. Whether you’re hauling heavy machinery or transporting gardening tools, understanding these categories and their distinct features will help you make an informed choice and ensure that you select the best trailer for your requirements.